Assembly module

A company as large as Heidelberger Druckmaschinen AG has various assembly areas with their own requirements. Detailed work plans are required in the pre-assembly area in particular. As the pre-assembly assemblies are not available as separately designed 3D models, production parts lists are indispensable for production.

Heidelberger Druckmaschinen AG uses Tio as a platform to load designed assemblies and to generate pre-assembly assemblies. This is done via an intuitive assignment of the components to the previously created work processes.

The planner uses an interface to SAP to obtain the information required for planning (e.g. standard times, material numbers, production resources). This planning is then documented and expanded into detailed assembly instructions. Heidelberg automatically writes the finished work plan, M-BOM and assembly instructions to SAP, thus providing the data for all further process steps.

Our cooperation with attenio is excellent. Tickets created are processed immediately and the team is passionate about their work. TIO is part of our digitalization strategy and fully integrated into our landscape. We use it to create our assembly parts lists and work plans, write them directly into SAP and use them at the workstation in assembly. For us, it is the comprehensive platform between design and the finished product.- Dr. Stefan Heizmann, CIO(2020) visit website

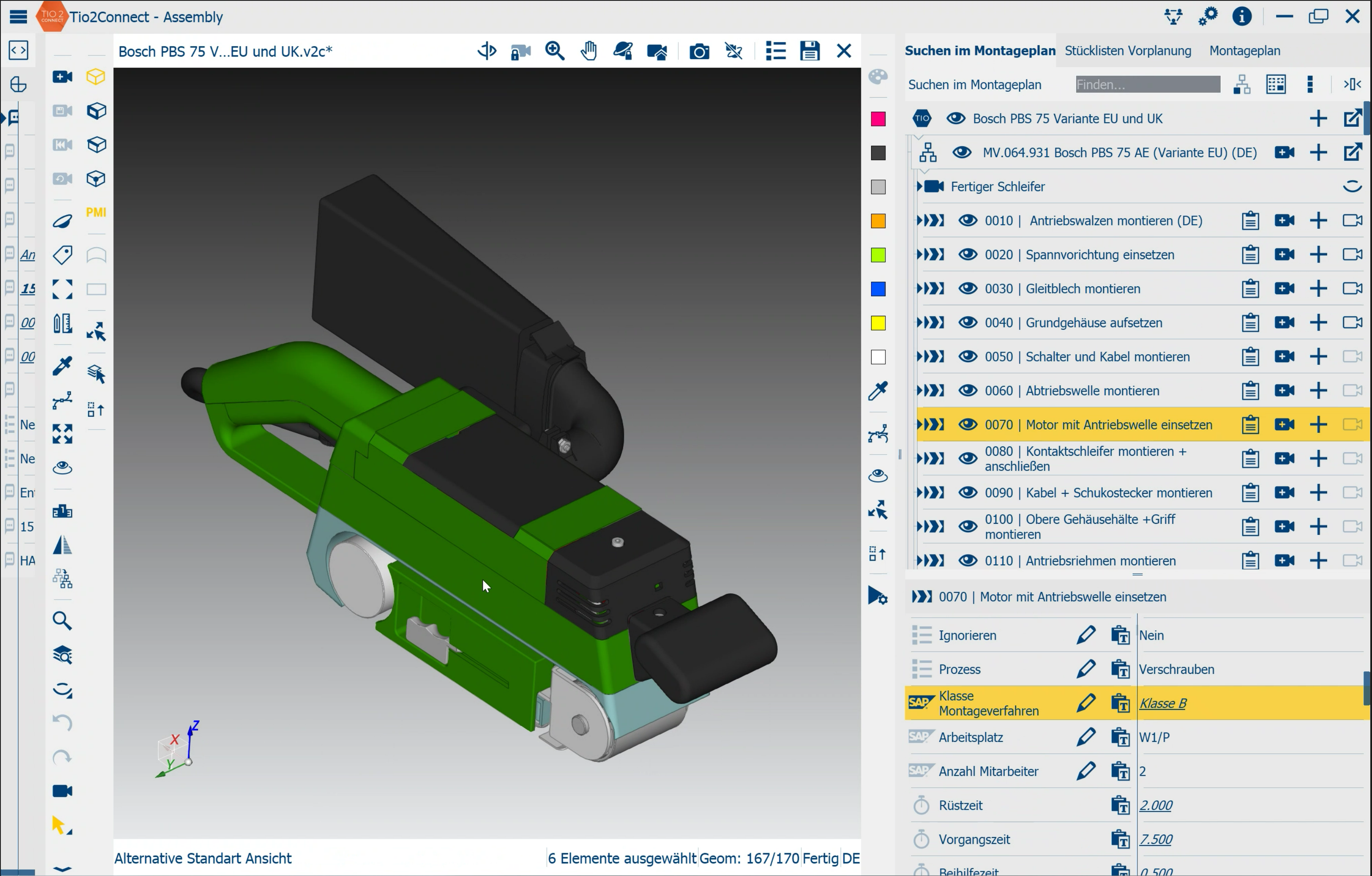

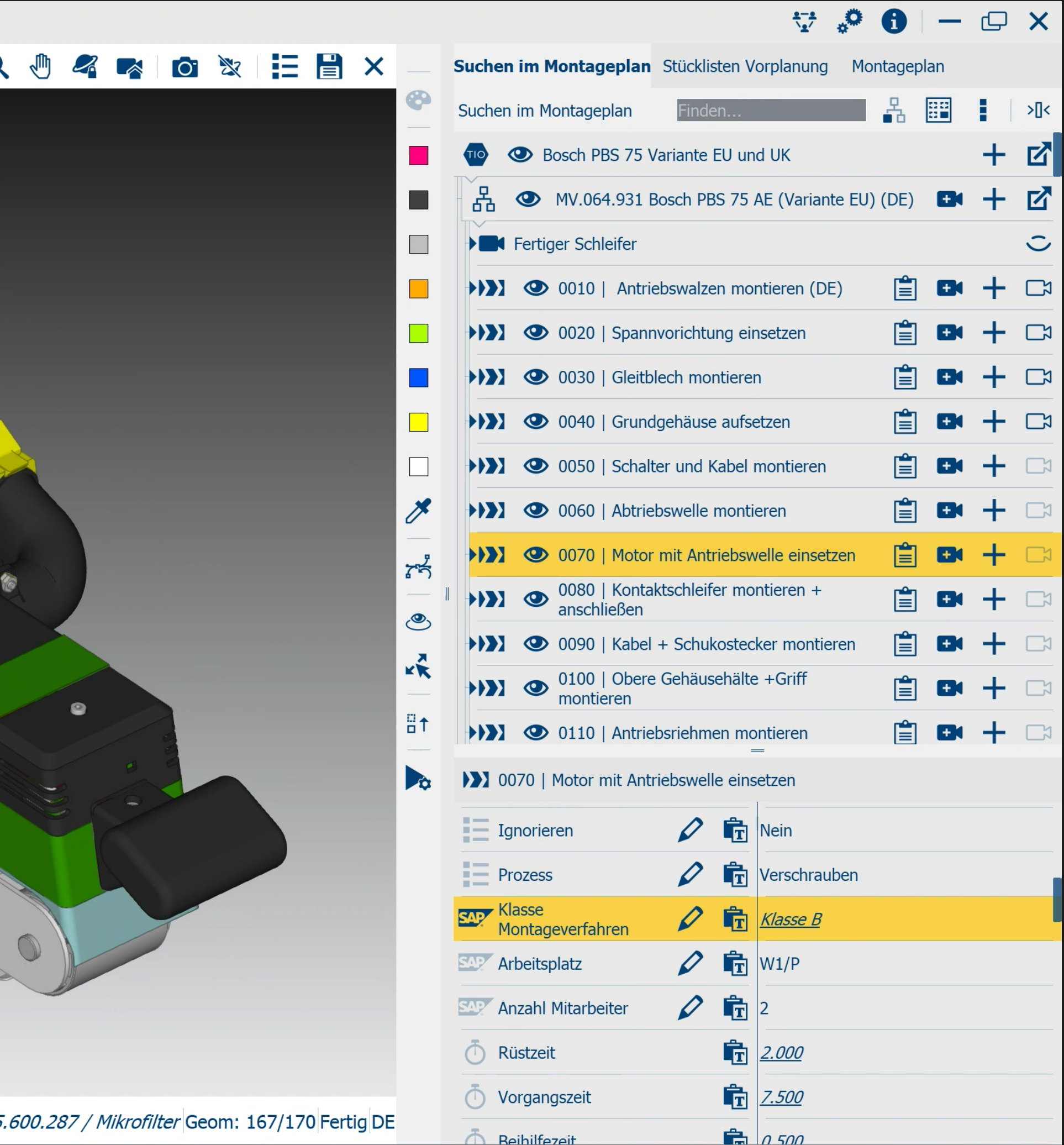

work plans

Tio helps you to create work plans intuitively. The structure in Tio corresponds to an ERP structure. Individual operations can be created for an assembly. The metadata of the operations can be set directly by the planner or can be taken from the ERP via an interface.

However, a work plan should not always be created from scratch. You have the option of loading your standard work plans from the ERP into Tio and further detailing them. Tio adapts to your requirements and can react to your assembly areas and help you to create the optimum work plan. Sequences or object dependencies are naturally taken into account and the reference to the virtual product (3D model) is available at all times.

Product revisions can have an impact on the work plan. The change assistant accompanies the planner and allows him to adapt it directly.

Manufacturing BOMs (M-BOM)

The assembly of a product is divided into different work steps, construction sites or even cycles. Production BOMs are indispensable for the targeted delivery of material. Tio allows you to create these visually and therefore intuitively based on the 3D model. Select components and drag & drop them onto the previously created operations or create a new material to which you can add components just as easily (for example, for welded assemblies or purchased parts).

You can integrate the resulting production parts list into your processes, either via exports or our interfaces to your ERP. We would be happy to advise you on how to set up such a process and integrate it into your IT landscape.

Of course, Tio is not limited to production BOMs, but also offers you the option of generating BOMs for service or, for example, packaging lists for transportation. Tio thus enables you to take a complete and flexible multi-BOM approach.

Restructuring

In addition to parts lists and work plans, production-ready 3D models are becoming increasingly relevant. Particularly with more complex products, design is often only carried out at assembly or system level. A visualization in assembly would therefore deviate from the production parts list.

As you work graphically in Tio, a corresponding 3D model for the specific work process is also created when the parts lists are created. At the touch of a button and without any additional effort, you can create 3D models that are suitable for the work process, regardless of which assemblies or systems the individual components come from. This module split works independently of your source systems and therefore also allows you to merge vendor components, for example.

The resulting 3D models can be conveniently displayed in production via the viewer.

Process Integration

Tio's 3D viewer grows with your requirements. If you want to visualize certain attributes or parts list information, you can have them automatically prepared in the background so that they are immediately available at the right moment.

AutomationIf topics such as revision, validity or storage of data in databases are important, you benefit from standard interfaces to fully integrate the 3D viewer into your processes.

interfacesSupporting functions:

Drag & Drop

Work visually in Tio. Simply use the mouse to select components in the input tree or directly in 3D, hold down the left mouse button and drag them intuitively to the desired work process. There is no need to copy or remove components.

Export

You can export the created work plans and parts lists at the touch of a button and use them for your subsequent processes. The exports can be provided in common formats such as .xlsx, .csv or .json.

Interfaces

Fully integrate Tio into your IT landscape and use existing standard interfaces.

learn moreParts list transformation

The drag & drop functionalities combined with a standardized work plan make it possible to restructure the product as required - assembly-oriented structure according to workstations, sorting according to purchased and in-house production parts for purchasing, structuring in pre-assembly assemblies or, for example, dividing into containers/boxes for later transport. An M-BOM or any other X-BOM can be created from an E-BOM in the shortest possible time.

watch Video